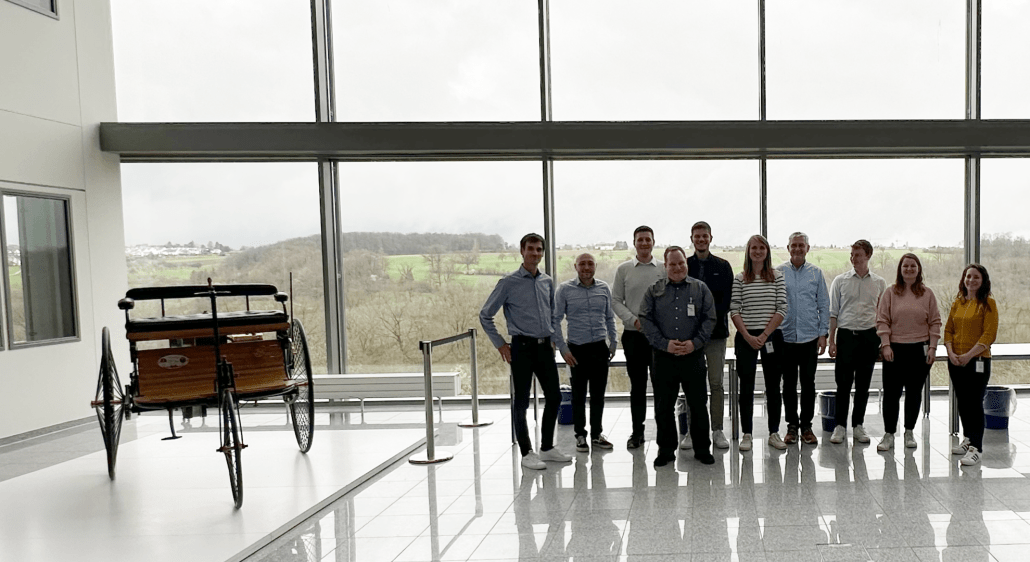

Ideation Workshop at FESTO

Last week, the team from the CliCE-DiPP research project met for an ideation workshop at the Festo production site in Ostfildern near Stuttgart. As an innovation leader, Festo offers pneumatic and electric drive technology for factory and process automation as well as state-of-the-art qualification solutions for the industrial environment. In addition to practical insights into individual FESTO products and the market environment in which these products are used, the aim of the workshop was also to generate ideas for new circular and sustainable value chains and economic models for the future. In fact, some very creative and exciting ideas emerged that will certainly be pursued in the future and perhaps even implemented in one form or another.

I would like to take this opportunity to thank Daniel Ditterich and the FESTO team for organizing the workshop and hosting us so well. It is exhilarating to see the areas in which some SMEs in Germany, such as FESTO, have specialized and are successful in the market with innovative products.

The fun fact of the day was that we used the same meeting room that Dr. Angela Merkel used as German Chancellor when she visited FESTO some years ago. As you can imagine, this provided additional motivation for the work – because “there was no alternative”. 🙂